-

Design

-

Specification

-

Download

-

How-to Videos

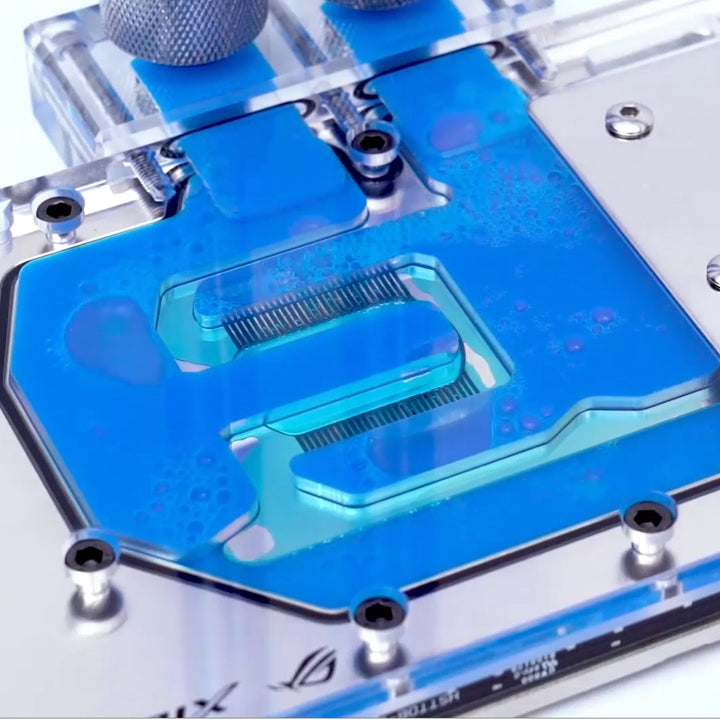

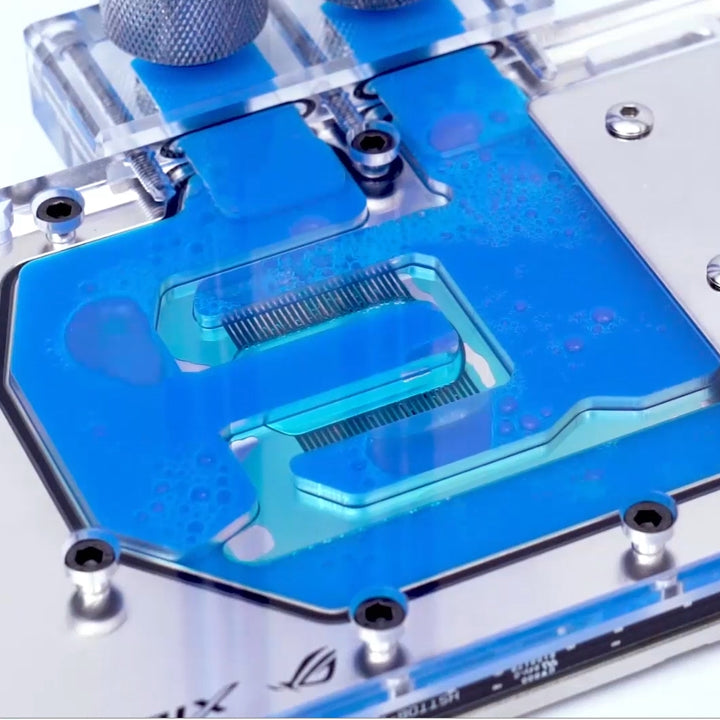

Thermaltake P1000 Pastel Coolant Series is designed with TT latest formula to be used as anti-corrosion protection fluid and heat-transfer medium for PC water-cooling. With the new liquid surface tension optimizer added to the formula, P1000 Pastel Coolant Series has minimized the risk of airlock and made filling up your system easy! The new formula also provides P1000 Pastel Series with color saturation and stability, as well as low viscosity that enables effective flow. Thermaltake P1000 Pastel Coolant Series is formulated to impress and simplify the process of setting up your water loop!

Tt LCS Certified is a Thermaltake exclusive certification applied to only products that pass the design and hardcore enthusiasts standards that a true LCS chassis should be held to. The Tt LCS certification was created so that we at Thermaltake can designate to all power users which chassis have been tested to be best compatible with extreme liquid cooling configurations to ensure you get the best performance from the best features and fitment.

Anti-Corrosive Solution

Corrosion protection for copper, brass, nickel, and aluminum.Antifreeze

Ensures coolant to run effectively under extreme weathers.Liquid Surface Tension Optimizer

By adding optimizer to increase the surface tension of the coolant, it minimizes the risk of airlock to accelerate the process of starting the system.

Thermaltake has made filling coolant easy. Thanks to the TT exclusive formula, the old days of repeatedly unplugging the system or waiting for 12 to 24 hours for the air to clear out after filling the loop is behind us. P1000 Pastel Coolant Series has minimized the risk of airlock by adding liquid surface tension optimizer. With P1000, it only takes about 5 to 10 seconds to start the system after filling the loop.

Due to the special formulated process of P1000 Pastel Coolant Series, it assembles a lot of qualities of pure water. Quality such as low viscosity enables effective flow of P1000 Pastel Coolant. Viscosity affects the fluidity of coolant, lower viscosity indicates less resistance therefore better flow of coolant. At 20°C, P1000 Pastel Coolant has 26.4% lower viscosity than other coolant and 25.8% lower at 40°C.

Coolant Viscosity at 20°C(m Pa‧s)

Coolant Viscosity at 40°C(m Pa‧s)

Being non-flammable, P1000 Pastel Coolant is a ready-to-use cooling solution with at least 3 years shelf life in airtight containers, providing great performance while preventing the entire cooling system – copper, brass, nickel, and aluminum – from corrosion.

Boiling Point:329°F(165°C)

Freezing Point:-4°F(-20°C)

Propylene Glycol < 6%

Water < 94%

Download MSDS

P1000 Pastel Coolant comes in five non-transparent colors; red, blue, white, green and yellow. The latest TT formula ensures color saturation, stability and duration.

P1000 Pastel Coolant Series is GREEN! Made with biodegradable materials, P1000 does not pollute the environment or bio accumulates. Thermaltake produced the P1000 Pastel Coolant Series with the environment in mind.

Cautions

Thermaltake recommends the following steps to be taken before

using the Pacific series radiators and water blocks

- To ensure a clean loop, flush and rinse your radiators and water blocks with distilled water prior to use.

- Do not use tap water or distilled water as your coolant, it may harm your loop and reduce performance.

- It is strongly recommended to use market proven pre-mix coolant, such as Thermaltake Coolant 1000. It offers great performance while protecting the entire liquid loop from corrosion.

- Before storing your water cooling components, please clean, rinse and dry. This will ensure a longer lifespan for your components.

Thermaltake recommends the following steps to be taken after

completing your water loop setup

- It is strongly recommended to use market proven pre-mix coolant, such as Thermaltake Coolant 1000. It offers great performance while preventing the entire cooling system – copper, brass, nickel, aluminum, and steel – from corrosion.

- Fill the reservoir with coolant and cycle the power on and off several times while the pump pushing the coolant into the loop.

- DO NOT let the pump run dry, when there is no liquid entering the pump turn off your power immediately

- Fill the reservoir to the top as it will prevent air from going into the pump

- If necessary tilt the system slightly from side to side to bleed the air out of the loop.

- Place some paper towels under fittings and joining points to test for leaks.

- Run the loop with the fill port open for about 24 hours to completely bleed the air out of the loop.

- Before starting, flush out your system correctly to prevent any coolant or unwanted particles sticking to your tubes, radiators and other cooling components.

- Coolant might fade over time.